We are all very impressed with your facility, capabilities, strength of knowledge in your products and especially satisfied with the quality of work you deliver. Thanks again to all in the Apex team and look forward to our next project together

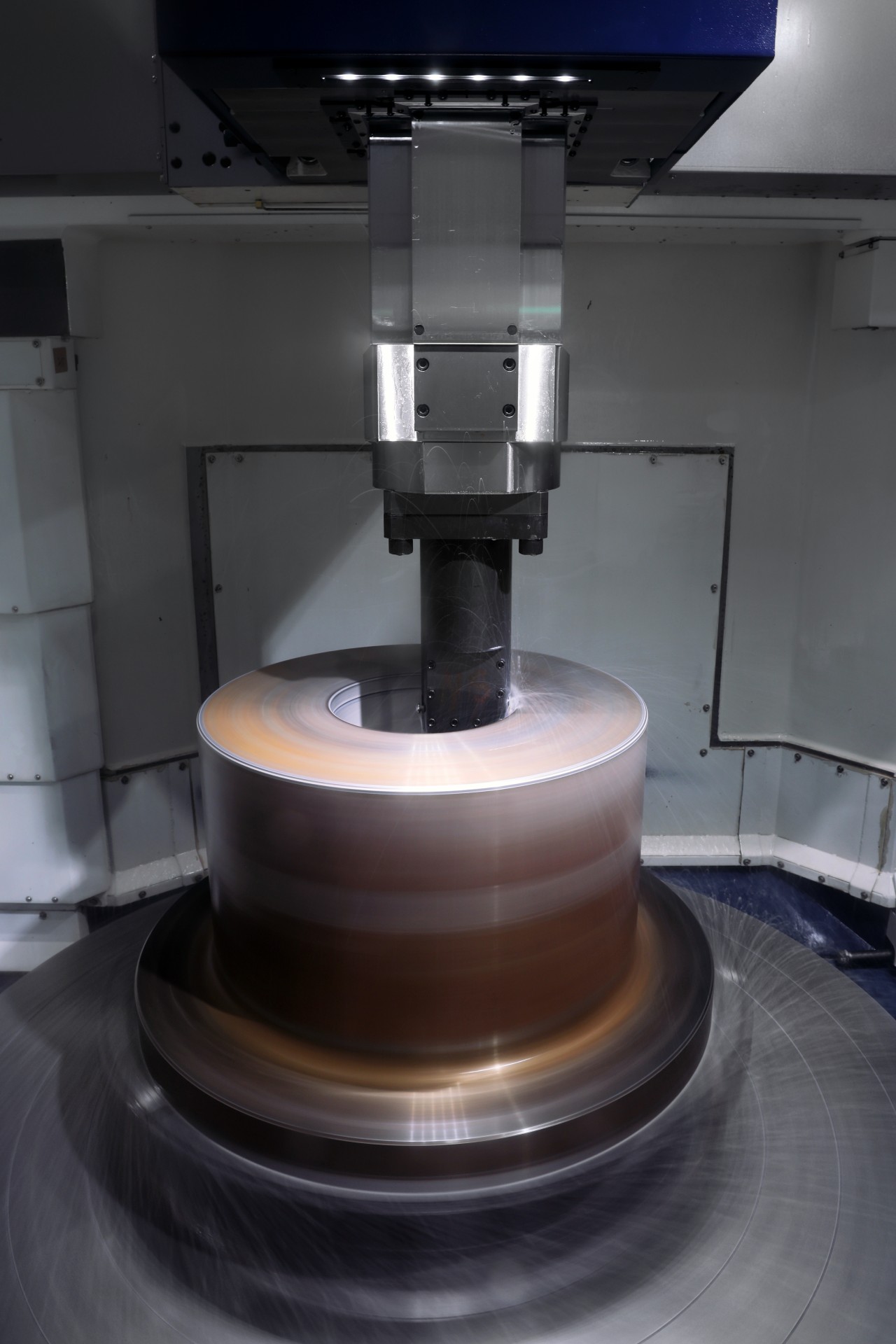

APEX ETG offers comprehensive machining services deliver precision components in a broad range of sizes, weights, or geometry. With advanced equipment and quick turnaround times, we transform your specifications into reality.

Our machining capabilities serve critical applications across heavy industry. From mining equipment requiring precise dimensional restoration to hydraulic components demanding tight tolerances, we deliver exceptional results. Manufacture new components in a broad range of sizes, weights and geometries.

Experience comprehensive machining solutions that complement our surface engineering services. Our integrated approach ensures optimal results for every component.

Non-Destructive Testing (NDT) & Metallurgical Laboratory Services

(NDT) and Metallurgical Laboratory Services are essential complements to a machine shop because they ensure quality, safety, and reliability of manufactured components without compromising their integrity.

Metallurgical labs analyze material composition, microstructure, and mechanical properties to verify that materials meet specifications. NDT ensures parts are free from cracks, voids, or inclusions that could lead to failure. Our in-house capabilities can help you meet all quality control requirements.

We are all very impressed with your facility, capabilities, strength of knowledge in your products and especially satisfied with the quality of work you deliver. Thanks again to all in the Apex team and look forward to our next project together

I just want to convey my appreciation for the good work that APEX has done for us. I have just been informed the components APEX repaired for us have exceeded all expectations. We have just crossed the 3x lifecycle benchmark. We would like to develop more applications with the team at APEX.

The game-changer for us to adopt laser cladding as our standard repair method was APEX’s willingness to undergo our supplier qualification process, to produce test tokens for laboratory and mechanical testing, and to adopt our quality control standards from the beginning. We look forward to develop more applications together with Apex ETG.

APEX ETG machines a wide range of materials and industrial components using manual and CNC milling machines (up to 2.0 m beds), CNC lathes (1–6 m between centres with up to 2200 mm swing), cylindrical grinders (5 m between centres), linishers (5 m between centres), and vertical turning lathes (1800 mm swing × 2600 mm height). These capabilities allow machining of mining components, hydraulic parts, drivetrain elements, shafts, pulleys, gears, pump housings, and custom heavy‑industry hardware in a variety of steels, alloys, and engineered materials.

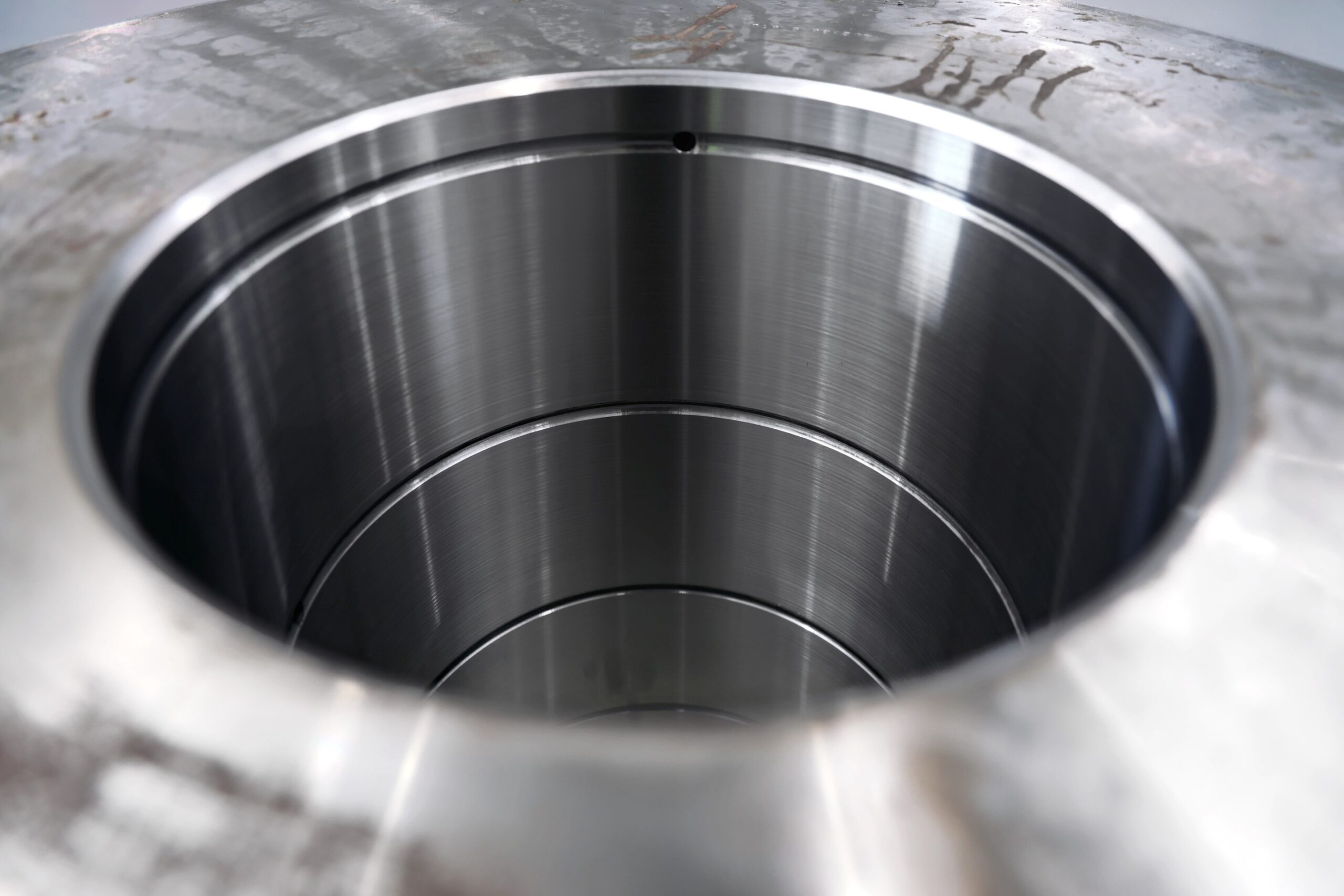

Yes. APEX ETG specialises in precision dimensional restoration, supported by CNC lathes, mills, grinders, and integrated pre‑ and post‑machining services that return worn parts to OEM tolerances with accuracy up to ±0.01 mm, enabling full reclamation of shafts, bores, bearing seats, seal lands, and mating surfaces while meeting or exceeding original specifications.

Metallurgical integrity is maintained through our in‑house metallurgical laboratory and NDT services, which verify material structure, hardness, and surface quality after machining. Techniques include microstructural analysis, hardness checks, and crack detection to ensure that machining does not introduce micro‑defects or compromise the component’s engineered properties.

Yes. The machining division is fully integrated with APEX ETG’s laser cladding, laser heat treatment, and welding services, allowing components to be pre‑machined for surface preparation, laser‑processed, and then machine‑finished in a single facility. This integration ensures optimal adhesion, geometry control, and final dimensional accuracy for refurbished industrial components.

Typical Turnaround times at APEX ETG are between 10 and 15 days. Our turnaround times are accelerated because APEX ETG maintains large‑capacity machines and a workshop optimised for fast response, allowing quick processing of both small and large components. Larger or heavier components may require additional setup or handling time, but the facility is designed to minimise delays through high‑capacity lathes, mills, grinders, and vertical turning lathes capable of processing substantial geometries efficiently.

APEX ETG achieves accuracy up to ±0.01 mm and surface finishes down to 0.1 Ra, validated through precision machining equipment and supported by metallurgical and NDT inspections. Dimensional quality is verified using calibrated measurement tools and process‑controlled machining workflows to ensure components meet all specified tolerances and finish requirements.

Yes. The combination of 3D scanning, CAD/CAM design, machining capability, metallurgical laboratory, and NDT services allows us to reverse‑engineer or rebuild worn or damaged components even when OEM drawings are unavailable. Dimensional analysis and engineered surface restoration enable accurate reproduction or enhancement of existing components.

APEX ETG achieves accuracy up to ±0.01 mm and surface finishes down to 0.1 Ra.

Yes. APEX ETG manufactures new components in a wide range of sizes, weights, and geometries, and also performs high‑precision repair and dimensional restoration work. Our services are suitable for OEM production, spare‑part manufacture, and refurbishment of industrial components.

APEX ETG supports unique one‑off machining, custom repairs, and large‑batch production, offering flexibility for prototype development, specialised rebuilds, or high‑volume industrial manufacturing, all within an integrated surface‑engineering workflow.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.