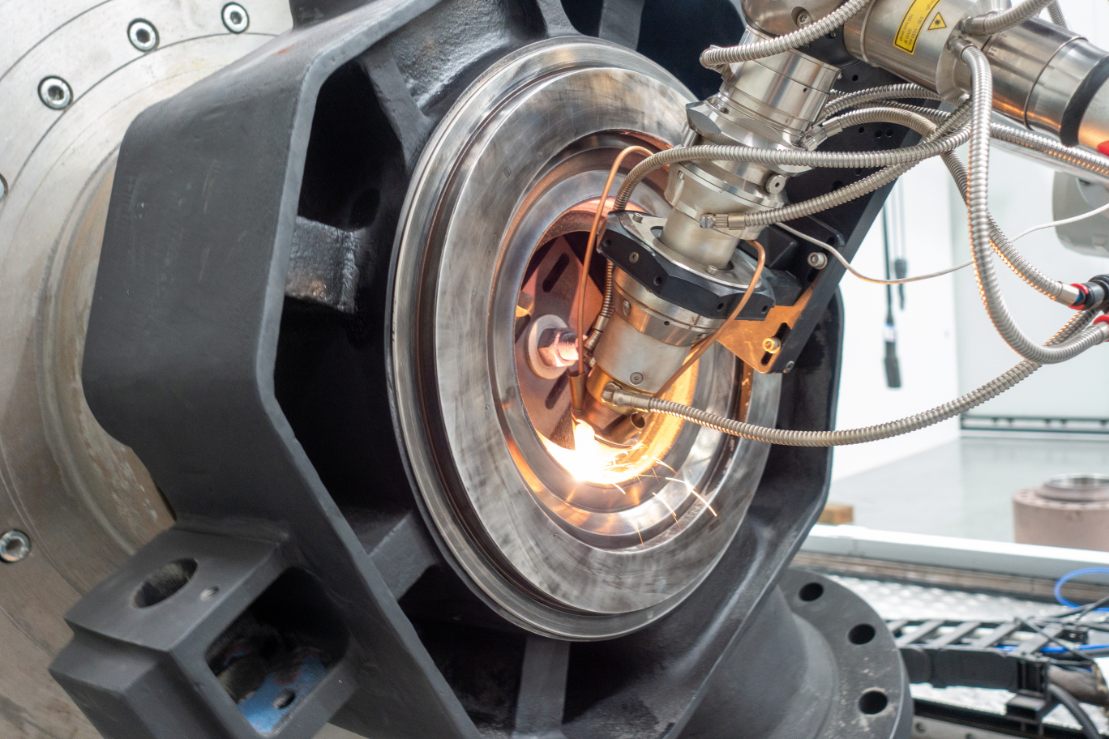

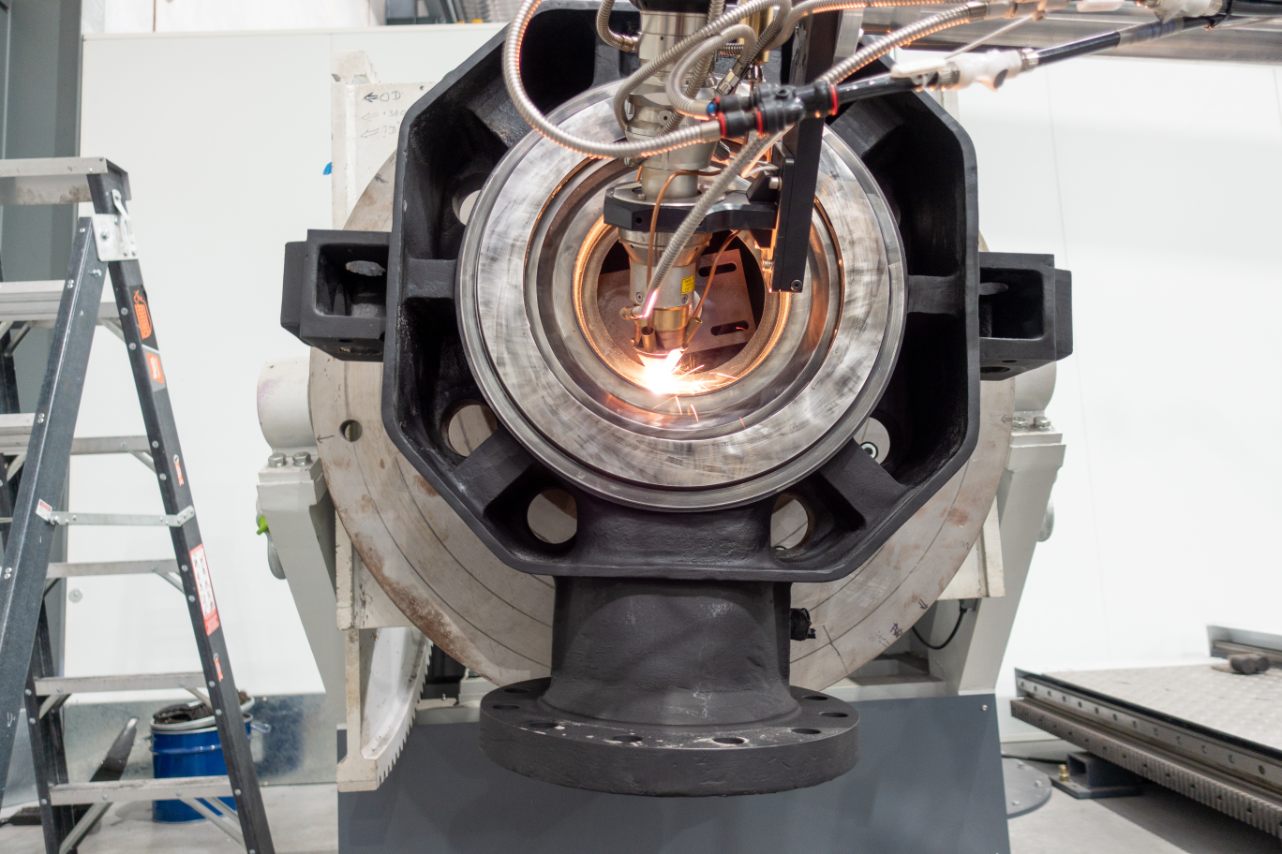

Maximise pump and valve component performance with laser cladding technology that combats wear, erosion, and corrosion.

APEX ETG delivers precision surface engineering solutions that restore critical dimensions, enhance sealing integrity, and extend service life.

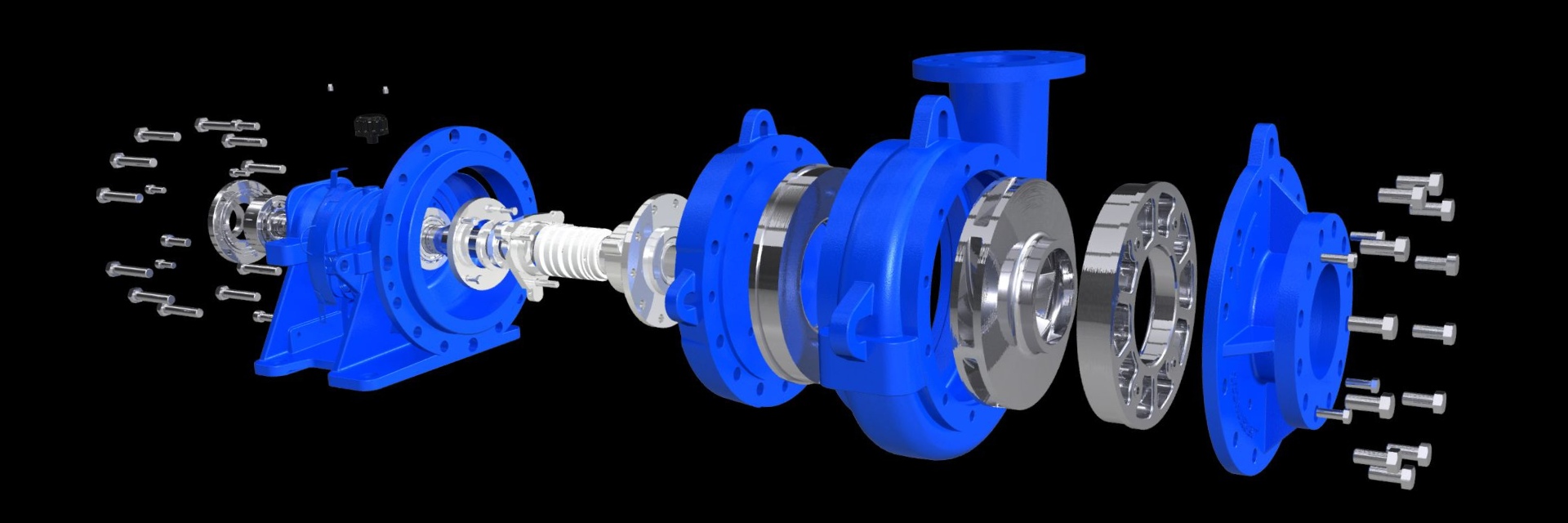

Laser cladding can be used to repair or strengthen the following:

Our technology is built for performance. By reclaiming and enhancing critical components, we help reduce downtime, extend service life, and improve equipment productivity — all with faster, more efficient turnaround times than conventional methods.

Slurries containing sand, minerals, and debris grind away pump impellers and valve seats rapidly. Our tungsten carbide laser cladding creates wear surfaces 5x harder than steel, maintaining hydraulic efficiency and preventing premature replacement of critical components.

Vapour bubble collapse generates intense localised forces that pit and erode pump surfaces. APEX ETG’s specialised cavitation-resistant alloys absorb impact energy and maintain smooth surface profiles, eliminating efficiency losses and extending impeller life dramatically.

Chemical processing and seawater applications expose components to severe corrosion that degrades sealing surfaces. Our corrosion-resistant alloys provide corrosive wear protection while maintaining the precise tolerances essential for reliable valve operation and pump performance.

Return worn pumps to original efficiency ratings through precision dimensional restoration. Our process rebuilds impellers, casings, and wear rings to OEM specifications while adding superior wear resistance.

Achieve leak-free valve operation with precise dimensional accuracy on critical sealing surfaces. Eliminate fugitive emissions and product loss while meeting environmental compliance requirements.

Pumps and valves form the heart of industrial operations, yet face relentless wear from abrasion, cavitation, and corrosion. When these critical components fail, entire processes shut down – costing thousands per hour in lost production. Traditional repair methods offer temporary fixes that compromise performance and require frequent intervention. APEX ETG’s laser cladding technology revolutionises pump and valve maintenance. Our metallurgically bonded coatings restore worn components to better-than-new condition while adding superior wear and corrosion resistance. Achieve tighter tolerances, improved efficiency, and dramatically extended service intervals with solutions proven across mining, oil & gas, and water treatment applications.

APEX ETG specialises in precision pump and valve restoration using advanced laser cladding technology.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced experts. APEX ETG has all of your application needs covered.