APEX Engineering Technology Group Pty. Ltd.

We’re a “one-stop surface solutions company” offering a comprehensive range of advanced hardfacing products and services for multiple industries and applications.

Take advantage of APEX ETG’s competence.

Our hardfacing services and products cater to the needs of a vast range of industries. Whether your application is large or small, our in-house capabilities will bring new life to your parts.

Contact us today to see how our solutions reduce operational costs, increase customer profitability, productivity, efficiency, and help meet environmental goals.

Take the first step in adopting a sustainable and greener process alternative.

APEX ETG is at the forefront of cutting-edge technologies for surface solutions with ongoing R&D collaboration opportunities for businesses looking to improve their efficiencies, long-term profitability and environmental goals.

Contact us for a free quote for in-house application services as well as comprehensive turnkey system design, training demonstration, robotics, and automation with aftercare support. APEX ETG has all of your application needs covered!

Our Business

-

Strategy & Business Model

Our mission is to provide unparalleled and innovative industrial coating services, engineering, high quality materials and state-of-the-art equipment to the heavy industry worldwide.

-

Our Values

APEX ETG’s values align with our target industries. Our diverse team work diligently to ensure operational efficiencies alongside cost control and profitability for our customers whilst meeting sustainable environmental targets.

-

Our Solutions

Our insights into the challenges and consequences of surface problems faced across industries enable us to provide solutions that add value and benefits to our customers.

-

Sustainability

Our solutions enable our customers to reach their sustainability targets and kick goals, such as climate commitments, operational green house gas emissions, net zero commitments and decarbonisation.

Working closely with our customers and becoming their trusted partner of choice.

-

Sustainability

Sustainability is at the heart of our operations from sourcing materials to employing innovative technologies to improve the lifespan and performance of equipment.

-

Environmental, Social, & Governance Targets

ESG goes hand in hand with our sustainability goals on waste reduction but also extends to our long term goals supporting decarbonisation efforts and greenhouse gas emission reductions, TFCD recommendations as well as our corporate social responsibility.

-

Innovation & Automation

We champion innovation and automation adding value to our customers’ business through faster and more efficient production processes resulting in reduced labour costs, improved safety, enhanced quality, and increased volume.

It also provides confidence of total process control for your projects with high-quality data that is accessible and easy to manage as well as replicable.

-

Equity, Diversity & Inclusion

Our diverse team thrives collectively through our core culture of equity and inclusion.

Collaboratively, our backgrounds and experiences help us solve problems with a range of perspectives whilst being agile, flexible and adaptive to a fast-paced environment.

-

Operational Efficiency

With an innovative mindset, we strive for higher operational excellence by providing professional knowledge alongside products and services that eliminate unnecessary inefficient operations.

This benefits our and our customers’ operations by minimising equipment downtime, maximising capacity utilisation, as well as providing safer operations for all personnel involved.

-

Profitability & Cost Control

Our core values and business acumen flows through to the bottom line.

By controlling and reducing production costs, we can help decrease net debt, increase net cash flow from operations and, ultimately, the return on capital employed for customers’ business.

Frequently Asked Questions

-

What is hardfacing?

Hardfacing refers to a process of metalworking where tougher, harder, wear-resistant material is put onto a base metal, to make it more durable or extend its lifespan. Hardfacing parts can mean saving between 25-75% of the cost of replacement parts.

-

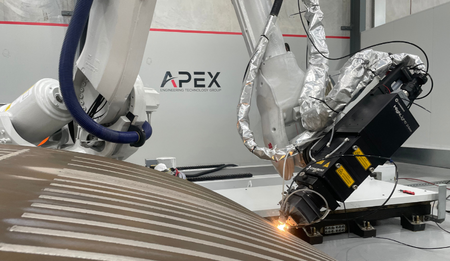

What is laser cladding?

Laser cladding is the newest and most effective hard-facing technology, providing a more efficient, cost-effective, reliable and sustainable weld overlay for refurbishing wear parts across a wide range of industries. Unlike traditional hardfacing, laser cladding uses a laser beam as the source of energy instead of an arc to fuse or alloy coating material and the base material together.

MoreLaser cladding is a welding process of adding a pure metal or an alloy in its powder form using a high-powered laser as the heat source to create the molten pool. The exposure time is short, which creates only a short delay as the cooling is quick avoiding distortion of the base metal. The result is a perfect, fully dense metallurgical bonding that corrects damaged components due to wear, corrosion, and abrasion. Laser cladding is also used for thermal management, electrical effects, protection, weight reduction and many more reasons for wear parts.

APEX ETG’s innovative, greener hardfacing technologies reduce operational costs and increase profitability, productivity, and efficiency.

-

What are the benefits of laser cladding?

Laser cladding has a significantly reduced heat-affected zone (HAZ), which means short cooling times. This creates many advantages;

– Base material dilution is minimal

– Almost no distortion of the base material

– The coating material retains many of its original properties, resulting in coatings with high hardness and excellent wear resistance, corrosion resistance and dimensional control.Other practical benefits include;

– Cost-effectiveness

– High accuracy

– No flaking or peeling -

What does ISO 9001 Certification mean for APEX ETG and its customers?

ISO 9001 Certification is a globally recognised standard for quality management systems. For APEX ETG, achieving this certification signifies our commitment to maintaining the highest standards of quality and efficiency in all our processes. For our customers, it means they can trust in the reliability and consistency of our products and services. It assures them that we have robust quality assurance measures in place, a culture of continuous improvement driving innovation, streamlined operations for prompt service, and a relentless focus on exceeding their expectations for satisfaction.